How we work.

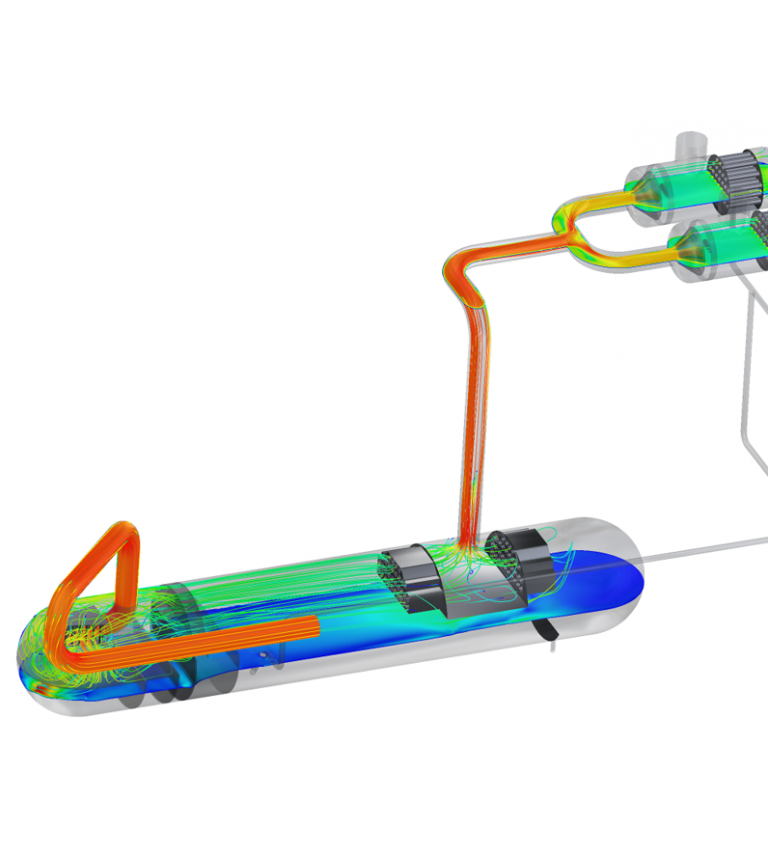

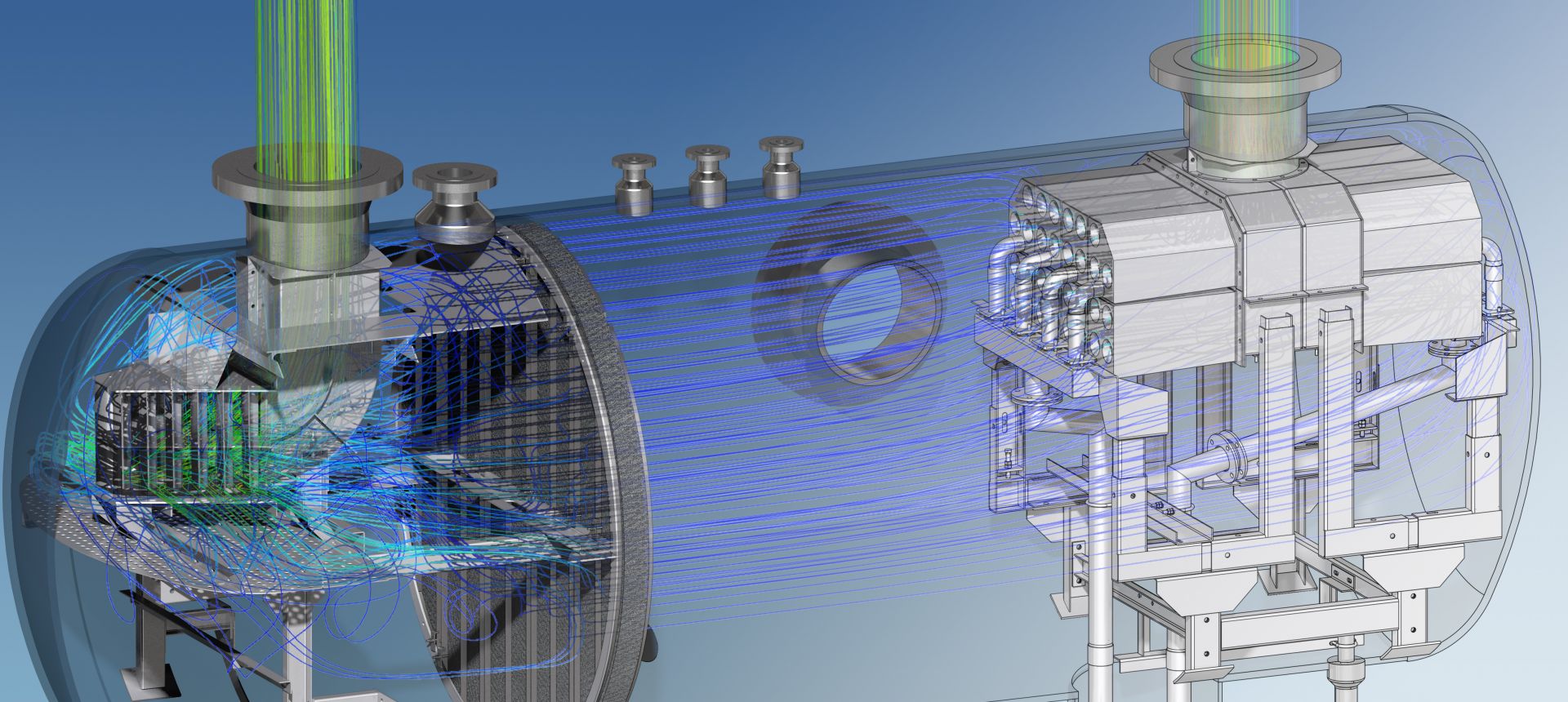

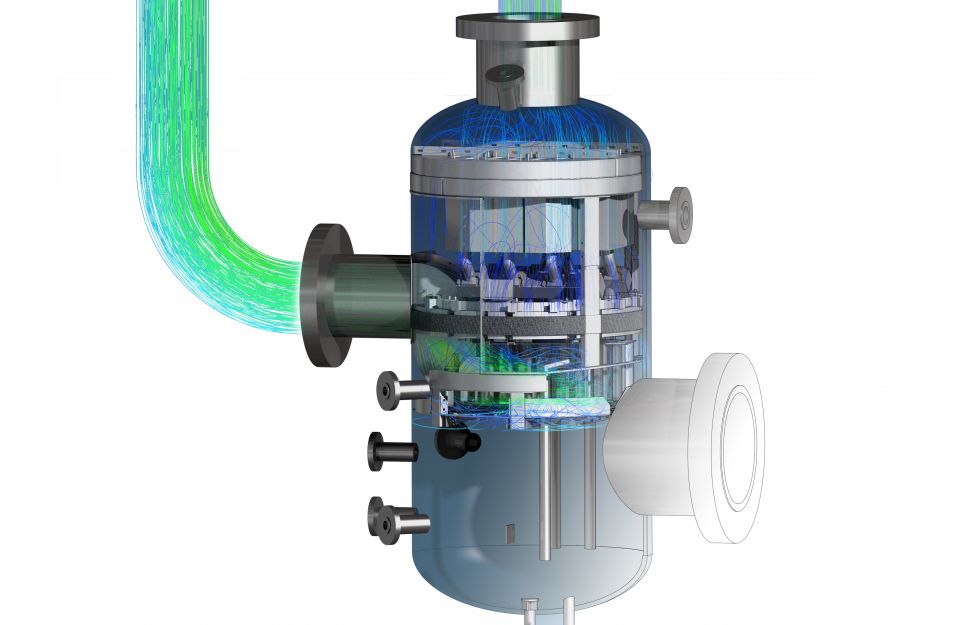

Separation is a critical operation in production and processing facilities. Failures and malperformance are extremely costly. Tap into Kranji Solutions’ expertise for reliable designs and remedy of any operational shortfalls.

Our Strengths

We see the project through to final implementation, resulting in less load on your organisation and your peace of mind that the envisaged solution is not compromised during project execution.

Want to know more?

Do you need detailed understanding of separator performance to:

Address mal-performance with significant impact on operations?

Optimise separation for increased through-put and changing conditions?

Develop new equipment or validate existing apparatus in controlled laboratory conditions?