Root Cause Failure Analysis of Sulphur Condensers

Kranji was engaged to undertake the main body of a root cause failure analysis related to condensers in the sulphur recovery unit of a large Middle-east gas processing facility

Our primary focus was in understanding the shell-side circulation and heat transfer, applying our experience in dynamic multi-phase CFD modelling and process heat exchanger technology. To facilitate this, we were required to undertake a wide range of supporting analyses.

Business Problem

Material failures had been experienced by the operator of the Sulphur Recovery Unit (SRU), over some years of operation. Un-planned shutdowns resulted in very costly lost production. In addition, expensive remediation work had been required.

The system involved was a Modified Claus SRU, with two parallel trains, each consisting of 3 condensers and 2 reactor beds, similar to that illustrated here.

Failures observed in the sulphur condensers were such that, the operator sought detailed understanding of the shell side behaviour including, the flow field liquid and vapour traffic, temperature, and heat transfer.

Summary of the Kranji Project Scope

A range of supporting analyses were undertaken to support Kranji's detailed dynamic CFD simulations, of the shell and tube heat exchangers, which condense sulphur vapour from process gases on the tube side. Cooling is provided in these exchangers by water boiling on the shell side.

Supporting Analysis

A range of supporting analyses were required for our study including:

- review of client’s historian data for the process, feed water and steam

- Aspen HYSYS® process simulations with embedded Sulsim™ thermodynamics

- heat exchanger simulations with the Aspen Shell & Tube Exchanger program

- benchmarking of cases against the process licensor’s Heat & Material balance data books

with these, Kranji defined agreed modelling conditions with the client, and extracted process properties for comprehensive CFD simulations.

CFD Verification of Process Side Flow Distribution

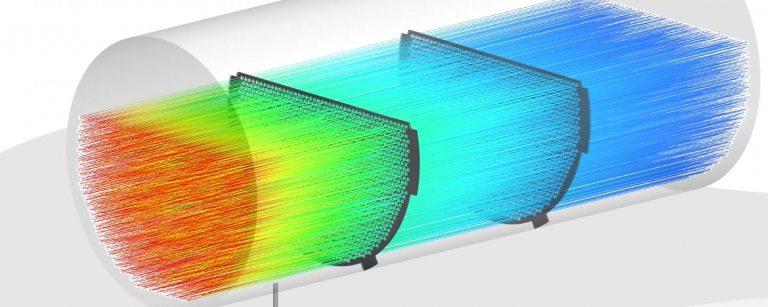

CFD analysis was undertaken for both condensers, to explore the extent of process flow maldistribution between condenser tubes, and to evaluate what influence that might have on the heat transfer behaviour.

Simulations were undertaken for both condensers with detailed meshing including the piping arrangement 35m upstream of the condenser inlet.

Analysis showed that there was modest maldistribution in both condensers with the largest deviation between tubes <11%. It was demonstrated that the thermal impact was relatively modest.

Shell-side CFD Modelling

A range of CFD modelling approaches was explored including, shell-side modelling with fixed heat flux and fully coupled modelling, combining tube-side cooling of the process vapours, with shell-side boiling and two-phase circulation.

Analysis considered velocity fields represented by streamlines, contours and vectors, vapour fraction contours and surfaces, liquid bulk, and surface temperature in addition to turbulent energy dissipation contours.

Our fully coupled simulations revealed how shell-side circulation was being disrupted by the method of introducing boiler feed water. This was shown to promote a highly-complex transient system of secondary recirculation eddies. Turbulence, the complex flow field, and impaired circulation were identified as contributory factors in the material failure mechanism.